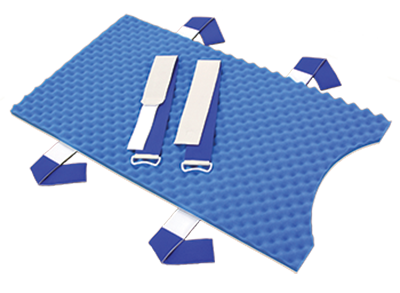

Medical sponge positioning pads are used in healthcare to provide comfort and support during surgeries, diagnostic tests, and post-operative care. Made from soft, absorbent materials like foam and coated with medical-grade materials for durability and hygiene, these pads require proper care and maintenance to remain effective and safe. This article offers best practices for cleaning, maintaining, and storing medical sponge positioning pads to ensure their longevity and effectiveness.

Why Proper Care is Essential

Medical sponge positioning pads are designed to enhance patient comfort during medical procedures by providing cushioning and support, preventing the formation of pressure ulcers, and ensuring the proper alignment of the body. Given that these pads are often in direct contact with the patient’s skin and can absorb bodily fluids such as sweat, blood, or exudate from wounds, ensuring that they are properly cleaned and maintained is crucial.

Improper care could lead to:

- Infection risks: Contaminated pads can contribute to cross-contamination and the spread of infections, especially in sterile medical environments.

- Loss of effectiveness: Pads that are not regularly maintained may lose their cushioning properties, which can affect patient comfort and the effectiveness of the positioning.

- Wear and tear: Over time, poor maintenance can result in damage to the pad’s structure, leading to decreased support, discomfort, or even patient injury.

Therefore, understanding how to properly clean, disinfect, store, and inspect medical sponge positioning pads is vital to ensure they continue to provide the intended benefits.

Cleaning and Disinfecting Medical Sponge Positioning Pads

Medical sponge positioning pads must be cleaned and disinfected in order to preserve hygienic conditions and avoid infections. The kind of sponge material and its intended function will determine the cleaning procedure. However, the general steps below will help ensure thorough cleaning without compromising the quality of the pad.

a) Follow the Manufacturer’s Instructions

Before cleaning, always refer to the manufacturer’s guidelines, as specific instructions may be provided for different types of sponge pads. Positioning pad manufacturers may recommend specific cleaning agents or techniques to prevent damage to the material or coating of the pad. These instructions should be prioritized to ensure the longevity of the pad and its compliance with medical standards.

b) Routine Cleaning of Sponge Pads

For standard cleaning, follow these steps:

- Surface Cleaning: Use a soft, lint-free cloth or disposable wipes that are designed for healthcare use. Clean the surface of the sponge positioning pad with a mild detergent solution or a medical-grade disinfectant. All surfaces should be cleaned, especially any folds or seams where bodily fluids could collect.

- Steer clear of strong chemicals: The pad’s surface may be harmed or its material integrity compromised by the use of harsh chemicals like bleach or abrasive cleaners. Choose cleaning agents that are non-abrasive and safe for medical use.

- Deep Cleaning: A thorough cleaning can be necessary if the pad is extremely dirty or discolored. If the sponge pad can tolerate water (refer to manufacturer guidelines), immerse it in warm water with a mild detergent. Gently scrape the surface with a soft brush to remove dirt, debris, and other impurities.

- Rinse and Dry: To get rid of any soap or cleaning solution, properly rinse the sponge with clean water after cleaning. Gently press out excess water (do not wring or twist) and allow the pad to air-dry completely before using it again.

c) Disinfection and Sanitization

Once the pad is cleaned, disinfecting it is essential to kill any lingering pathogens. Follow these steps:

- Use disinfectants that have been approved by the medical community. These disinfectants, which are effective against a variety of hospital-associated infections, including bacteria and viruses, are based on alcohol, hydrogen peroxide, or quaternary ammonium compounds.

- Contact Time: Ensure that the disinfectant is left on the pad for the required amount of time to achieve full microbial efficacy. To determine the proper contact time, adhere to the manufacturer’s recommendations.

- Drying After Disinfection: Once disinfected, the positioning pad should be air-dried in a clean, well-ventilated area. Do not use the pad until it has been completely dried to avoid the growth of mold or mildew.

d) Handling Soiled Pads

If a medical sponge positioning pad becomes heavily soiled, such as with blood, bodily fluids, or exudates from surgical wounds, it’s crucial to handle it with care:

- To avoid coming into touch with any contaminants, put on the proper personal protective equipment (PPE), such as gloves and face shields.

- If necessary, place soiled pads in designated biohazard waste bags before cleaning or disposing of them. Make sure that the biohazard waste is managed in accordance with the infection control procedures of the medical facility.

Regular Inspections and Maintenance

Proper maintenance goes beyond cleaning. Regularly inspecting the condition of medical sponge positioning pads ensures that they remain effective in supporting the patient and preventing injury. Here’s how to properly maintain your positioning pads:

a) Check for Damage

Positioning pads are prone to normal wear and tear, particularly with repeated use. Over time, the foam or sponge material may compress, lose its shape or tear. These damages could compromise the effectiveness of the pad.

- Look for Tears or Rips: Check the pads for any visible tears, rips, or punctures, particularly around the edges, seams, or high-stress areas where the pad is most likely to experience wear.

- Loss of Firmness: Feel the foam or sponge for softness or compression. Pads that have lost their cushioning properties should be replaced to maintain the support needed during procedures.

- Deformation: Any deformation or crumbling of the pad material may indicate that the pad is no longer providing adequate pressure relief. Replace the pad to prevent patient discomfort or injury.

b) Check for Discoloration

Medical sponge positioning pads that show signs of discoloration or staining, particularly around seams or pressure points, may have absorbed bodily fluids, sweat, or other contaminants. This could indicate that the cleaning process was not sufficient or that the pad is no longer hygienic for use. In such cases, the pad should be disinfected thoroughly or replaced if cleaning is ineffective.

c) Pressure and Firmness Adjustments

Some positioning pads may lose their firmness after repeated use. This can result in reduced effectiveness in providing proper positioning or pressure relief. If the pad is air-filled or adjustable, check for air leaks and ensure the appropriate inflation levels are maintained. Some pads allow for fine-tuning of firmness or positioning, so it’s important to regularly check the air pressure or adjust the pad to provide the right level of support.

Storing Medical Sponge Positioning Pads

Proper storage of medical sponge positioning pads is essential to maintain their shape, cleanliness, and integrity. When not in use, follow these guidelines:

a) Store in a Clean, Dry Area

Always store sponge positioning pads in a clean, dry, and cool environment, away from direct sunlight or sources of excessive heat. The pad material may deteriorate or lose its shape if exposed to heat or sunshine.

b) Avoid Overcrowding

Store the pads in an organized manner that prevents them from being bent, folded, or squished. Overcrowding can cause deformation, which may reduce their effectiveness when used again.

c) Ensure Airflow

To avoid the growth of bacteria or mold, ensure that stored pads have good airflow and are not kept in airtight bags or containers unless specifically recommended by the manufacturer. This will keep the pads dry and safe for use in the future by preventing moisture buildup.

Replacing Worn or Damaged Pads

Despite proper cleaning and maintenance, medical sponge positioning pads will eventually need to be replaced. Signs that a pad should be replaced include:

- Loss of cushioning or rigidity.

- Visible flaws like holes, rips, or cracks.

- Discoloration or persistent staining.

- Failure to maintain proper positioning or support.

Regularly assess the condition of the pads and replace them when necessary to ensure continued patient comfort and safety.

Conclusion

Medical sponge positioning pads are essential for patient support, comfort, and safety during healthcare procedures. For them to remain effective, hygienic, and long-lasting, proper care and upkeep are essential. By following cleaning and maintenance guidelines, healthcare providers can maintain pad quality, improving patient outcomes and safety.